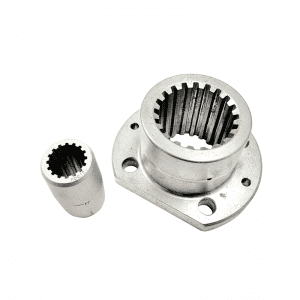

Profesjonele ynformaasje

| Produkt namme | Spline gear |

| Materiaal | C45, 40Cr, 20CrMnTi, 42CrMo, Koper, RVS ensafuorthinne as per jo oanfragen. |

| Ferwurking | Smeden, Machtigingsformulier, Hobbing, Frezen, Scheeren, Slijpen, Heat behanneling ...... |

| Heat Treatment | Carburizing, Induction, Flame, Nitriding ...... |

| Main Machines | Gear Hobbing Machines, Gear Shapers (Gealson, Moude), draaibank, gear Scheermasines, gear frezen, gearslijpmasines en CNC-sintra.... |

| Wêrom kieze ús | • 100% fabrikant • Ryk produksje ûnderfining • Avansearre GEAR Machine • Strikt Quality Control System • Fleksibel MOQ •Punctual levering • Excellent en Erfaren Team |

Reguliere materialen en waarmtebehannelerst

| Reguliere materialen en waarmte behanneling | |||||

| GB/JB | DIN | JIS | SAE/AISI | Case Hardening | Case Hardness |

| 40 CrNiMo | 34CrNiMo6 | SNCM439 | 4340 | Nitriding | 46-50 HRC |

| 20 CrMo | 20CrMo44 | SCT42 | 4119/4118 | Carburizing | 42-45HRC of 55-60HRC |

| 20 CrNiMo | -- | SNCCM220 | 8620 | Carburizing | 55-60 HRC of 58-62 HRC |

| 20 CrMnTi | -- | -- | -- | Carburizing | 55-60 HRC |

Heat Treatment Cycle: Carburizing / Nitriding → Normalize → Quench → Clean → Temper → Shot Blast

| Precision Grade, Prosesmetoaden en tapassing Standert: GB 10095-88, DIN 3961-78; ISO 1328-75 / GB 10095-88; JIS 1702-74; AGMA 39003-71

| |||||

| Precision grade | Klasse 5 | Klasse 6 | Grade 7 | Grade 8 | Grade 9/10 |

| Module berik | Gleason M10~M40 | Spur / helical M3~M40 | Spur / helical M3~M40 | Spur / helical M3~M40 | Spur / helical M3~M40 |

| Buitendiameter (max) | φ1500 mm | Φ2000 mm | Φ2000 mm | Φ3000 mm | Φ3000 mm |

| Finale proses | fyn slypjen | fyn slypjen of skeeren | slypjen, skeeren, lappen | skeere | -- |

| Tosken Oerflak Roughness | Ra 0,8 μm | Ra 0,8 μm | Ra 1,6 μm | Ra 1,6-3,2 μm | Ra 3,2-6,3 μm |

| Oanfraach

| Mjitte gear

| lokomotyf

| kraanforging machine trekkers, frachtweinen universele ferminder

| kraan boerebedriuw masines forging machine trekkers, frachtweinen universele ferminder | kraan boerebedriuw masines forging machine myn masines trekkers |

| Wêrom kieze US | • 100% fabrikant | • Ryk produksje ûnderfining

| • Avansearre GEAR Machine

| • Strikt Quality Control System

| • Fleksibel MOQ • Fast levering

|

Ferpakking:

| Carton Grutte | 29 * 20 * 13 CM as fersyk fan klant |

| Pallet grutte | 120 * 80 * 80 CM as fersyk fan klant |

| Trochrintiid | 3-7 wurkdagen as usual.It sil basearre op de detaillearre oarder kwantiteit. |

| Packing Details | Metoade 1: Krimp film, dan bulk laden |

| Metoade 2: Krimpfilm + doaze + pallet / houten koffer | |

| Metoade 3: PP + houten koffer | |

| Metoade 4: As per easken fan klanten of ûnderhannele |